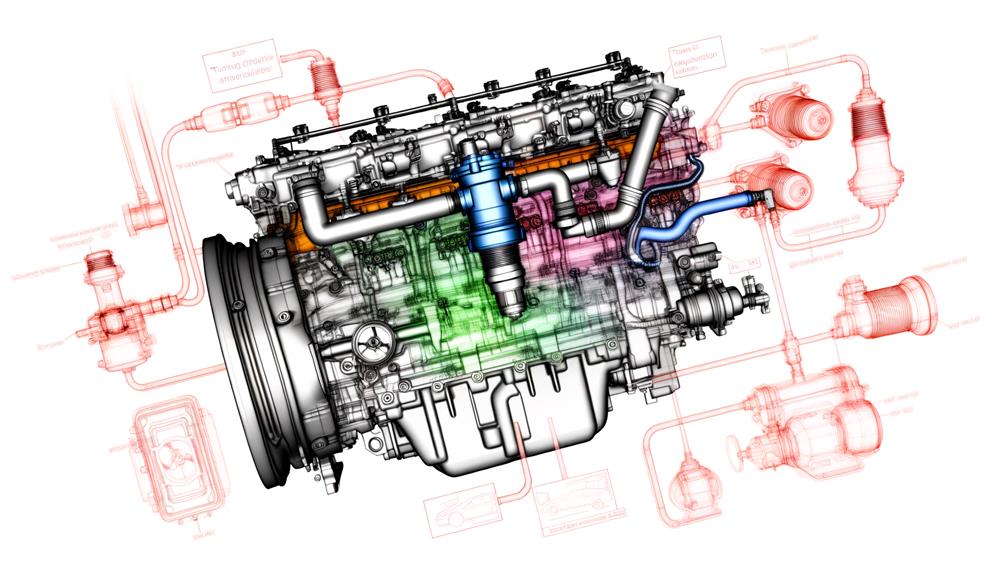

As we navigate the intricate maze of diesel fuel efficiency tuning, it's clear that every turn and twist can lead to a myriad of outcomes. We're aware that a multitude of factors come into play, from the precision of fuel injection timing to the critical balance of the air-to-fuel ratio.

Moreover, we can't overlook the role of advanced technologies such as turbocharging and intercooling or the potential gains from exhaust system modifications. And let's not forget the foundational importance of maintaining high-quality fuel filters and pumps.

As we explore these components, we're on the cusp of understanding how each adjustment and upgrade can either enhance performance or lead us down a road of compromise. The question remains: how do we optimize these variables to achieve the perfect harmony of power, efficiency, and longevity in our diesel engines?

Stay with us as we uncover the layers that define the art and science of diesel tuning.

Understanding Fuel Injection Timing

To optimize diesel engine performance, it's crucial to precisely calibrate the timing of fuel injection, ensuring that fuel is delivered at the exact moment when the engine can utilize it most effectively. We understand that the liberation of our engines from inefficiency and high emissions lies in this fine-tuning. Optimal injection timing can significantly reduce fuel consumption and improve the power output, while also decreasing harmful exhaust emissions.

We're analyzing the engine's combustion cycle to identify the pinnacle of efficiency. Advanced injection timing, where fuel enters the cylinder early, can lead to incomplete combustion, producing smoke and unburnt fuel. Conversely, if we delay the timing excessively, we risk higher peak combustion temperatures, which can cause nitrogen oxides to form, contributing to air pollution and engine wear.

Therefore, we meticulously adjust the timing, considering factors like engine speed, load, and temperature. We're seeking a balance that delivers power and efficiency without compromising engine lifespan or the environment. Our goal is to liberate our engines from the constraints of poor performance and align them with a future that values both robustness and responsibility.

Every adjustment is a step towards a more sustainable and powerful diesel engine.

Importance of Air-to-Fuel Ratio

While adjusting injection timing is critical, we must also focus on the air-to-fuel ratio, as it's fundamental to achieving optimal combustion and engine performance. This ratio determines how completely fuel is burned, which in turn affects power output and emissions.

Here's a closer look at the role of the air-to-fuel ratio:

- Precision in the air-to-fuel ratio ensures:

- Maximized fuel efficiency: Only the necessary amount of diesel is combusted.

- Reduced emissions: Proper combustion minimizes harmful pollutants.

- A suboptimal air-to-fuel ratio results in:

- Incomplete combustion: Excess fuel or air leads to soot and unburnt hydrocarbons.

- Increased maintenance: Engines suffer from carbon deposits and wear.

We understand that freedom from inefficiencies and unnecessary costs is crucial. By meticulously calibrating the air-to-fuel ratio, we liberate engines to perform at their peak while conserving resources. Our approach is to analyze and adjust this ratio with a precision that speaks to the analytical minds seeking to unlock the full potential of their diesel engines.

Through this, we offer a path to liberation from the constraints of subpar engine performance and the environmental impact of inefficient fuel combustion.

Turbocharging and Intercooling Effects

Harnessing the power of turbocharging and intercooling, we significantly enhance diesel engine efficiency by forcing more air into the combustion chamber, thereby improving the air-to-fuel mixture and combustion process. Turbochargers capitalize on exhaust gas energy to drive a turbine, compressing incoming air and increasing its density before it enters the engine. This denser charge contains more oxygen, which is essential for more complete fuel combustion.

Intercoolers take this process a step further. They reduce the temperature of the compressed air from the turbocharger before it enters the engine. Cooler air is denser still, packing an even greater amount of oxygen into the same space. This cooler, denser air charge not only supports better combustion but also helps in mitigating the risk of engine knock, a common issue when tuning for high performance and efficiency.

We're acutely aware that these modifications can lead to a dramatic liberation of performance potential. However, it's crucial to balance the boost pressure and intercooler capacity to prevent undue stress on the engine. Proper calibration ensures longevity alongside the performance gains, making turbocharging and intercooling pivotal components in diesel fuel efficiency tuning.

Exhaust System Modifications

Moving beyond the air intake system, we turn our attention to exhaust system modifications which can further augment diesel engine efficiency by optimizing the expulsion of waste gases. As we delve into the intricacies of exhaust flow dynamics, it's essential to recognize how the careful recalibration of these systems liberates engines from the shackles of inefficient designs, thereby enhancing overall performance.

To create vivid imagery:

- High-Flow Exhaust Systems:

- Think of the engine as a seasoned athlete; the high-flow exhaust is akin to unrestrictive breathing, allowing for swift and powerful exhalations.

- Envision a wide-open highway as opposed to a congested street, facilitating a quicker path for exhaust gases to escape.

- Mandrel-Bent Tubing:

- Picture the smooth interior of a tube slide, ensuring that exhaust gases glide without turbulent interruptions.

- Imagine water flowing through a straight pipe versus a kinked hose, symbolizing the efficiency gains from uninterrupted exhaust flow.

We're aware that these modifications must be executed with precision, as they're critical in reducing back pressure and enhancing the diesel engine's capacity to breathe effectively. This liberation from OEM constraints not only boosts power but also contributes to fuel economy, striking a balance between performance and sustainability.

Upgrading Fuel Filters and Pumps

Having explored how exhaust system modifications can optimize the release of waste gases, we now turn our focus to the importance of upgrading fuel filters and pumps, integral components that ensure the delivery of clean fuel for efficient combustion. A diesel engine's performance is critically dependent on the quality and consistency of its fuel supply. Substandard fuel filtration can result in contaminants causing wear, tear, and inefficiencies, ultimately crippling engine performance and longevity.

Upgrading fuel filters to models with finer micron ratings arrests more impurities, safeguarding injectors and maintaining the integrity of the fuel system. This proactive measure directly correlates with a sustainable boost in fuel efficiency, as a cleaner burn is achieved with contaminant-free diesel. We're not simply changing parts—we're enhancing the engine's resilience against pollutants that can degrade performance over time.

Similarly, aftermarket fuel pumps can yield significant gains. High-performance pumps augment fuel delivery, especially vital under high-load conditions where demand surges. By ensuring a steady, adequate fuel flow, we prevent the starvation that can lead to inconsistent combustion and inefficient fuel use.

Investing in these upgrades is a strategic choice for those who seek liberation from the constraints of stock configurations. It's a commitment to extracting every ounce of potential from their diesel powerplants, pushing the envelope of performance, efficiency, and reliability.

Conclusion

In conclusion, we've uncovered that optimal diesel performance hinges on precise injection timing, a balanced air-to-fuel ratio, and the efficiency gains from turbocharging and intercooling.

Modifying the exhaust system can further enhance airflow, while upgraded filters and pumps ensure clean and consistent fuel delivery.

Collectively, these factors contribute to a finely-tuned diesel engine that delivers superior fuel efficiency and robust power output, embodying the pinnacle of diesel engineering expertise.